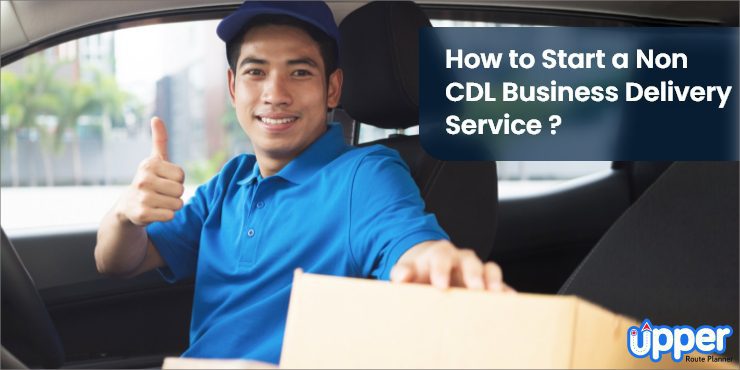

If you are looking to start a non-CDL car hauling business, there are a few things you will need to do. First, you will need to obtain the proper licenses and permits from your state. Next, you will need to purchase or lease a vehicle that is large enough to transport multiple vehicles at once.

Finally, you will need to find customers who are in need of your services. Once you have all of these things in place, you can begin operating your business.

- To start a non CDL car hauling business, you will need to obtain the necessary permits and licenses from your state and local government

- You will also need to purchase insurance for your business

- Next, you will need to purchase or lease a truck that is large enough to transport multiple vehicles at once

- Once you have obtained all of the necessary permits, licenses, and insurance, you will be ready to start your car hauling business!

Non Cdl Car Hauler Requirements

If you’re interested in becoming a car hauler, there are a few requirements you’ll need to meet. First, you’ll need a valid driver’s license and clean driving record. You’ll also need to be at least 21 years old and have a clean criminal record.

Finally, you’ll need to have some experience driving large vehicles.

Once you’ve met all of the requirements, you’ll need to obtain a commercial driver’s license (CDL). To do this, you’ll need to pass a written exam and skills test.

Once you have your CDL, you’re ready to start hauling cars!

There are a few things to keep in mind when hauling cars. First, always inspect your vehicle before loading any cars onto it.

Make sure everything is secure and that there’s nothing that could potentially damage the cars during transport. Second, drive carefully! Remember that you’re responsible for ensuring the safety of the vehicles you’re transporting.

Take your time and follow all traffic laws.

By following these simple tips, you can become a successful car hauler in no time!

Non Cdl Car Hauling Jobs

If you’re looking for a new career with great pay and plenty of opportunity for advancement, then non CDL car hauling jobs might be the perfect fit for you! Here’s everything you need to know about this exciting field.

What is Non CDL Car Hauling?

Non CDL car haulers are responsible for transporting vehicles from one location to another without the need for a commercial driver’s license. This can include cars, trucks, vans, and even boats! Most non CDL car haulers work for auto transport companies, but there are also opportunities to work independently.

What are the Requirements?

To qualify for non CDL car hauling jobs, you’ll need a clean driving record and a valid driver’s license. You’ll also need to be physically strong enough to load and unload vehicles onto the trailer.

Some companies may require additional training or certification before hiring you.

What are the Benefits?

How to Start a Non Cdl Hot Shot Business

Are you interested in starting your own hot shot business? If so, there are a few things you need to know. First, hot shot businesses require a commercial driver’s license (CDL).

However, you can start a non-CDL hot shot business if you use a smaller vehicle that does not require a CDL. Second, hot shot businesses are typically home-based businesses, which means you will need to have adequate space to store your equipment and vehicles. Finally, hot shot businesses usually specialize in hauling oversize or overweight loads.

This means you will need to obtain the proper permits and insurance for your business.

Now that you know the basics of starting a hot shot business, let’s dive into the details. To get started, you will need to purchase a truck and trailer that meet the size requirements for your state.

In most states, this means having a truck with at least a 16 foot bed and trailer with at least an 8 foot bed. You will also need to obtain the proper registration and insurance for your vehicles. When it comes time to haul loads, be sure to check with local authorities to ensure that you have the proper permits.

Finally, don’t forget to promote your new business!

Non-Cdl Car Hauler Owner Operator

There are many reasons to become a non-CDL car hauler owner operator. The most common reason is that it allows you to haul more cars without having to obtain a commercial driver’s license (CDL). This can save you time and money, as well as open up opportunities to haul other types of loads.

Another reason to become a non-CDL car hauler owner operator is that it can be less expensive to insure your vehicle. Insurance rates are based on the type of vehicle being insured, and non-commercial vehicles typically cost less to insure than commercial ones. This can save you hundreds of dollars every year on your premiums.

Lastly, becoming a non-CDL car hauler owner operator gives you the freedom to choose your own work hours and days. You’re not tied down to set schedules like with some commercial trucking jobs. This flexibility can be great for those who want to spend more time at home with their families or pursue other interests outside of work.

How Many Cars Can You Haul Without a Cdl

If you have a regular passenger car or truck, you can haul up to three cars without needing a commercial driver’s license (CDL). This is according to the U.S. Department of Transportation’s Federal Highway Administration (FHWA). If you exceed this limit, then you must get a CDL.

The rules are different for trailers since they have their own weight restrictions.

Starting a Non Cdl Box Truck Business Checklist

Starting a non-CDL box truck business can be a great way to get your business off the ground. However, there are a few things you need to keep in mind when starting up this type of business. Here is a checklist of what you need to do in order to get started:

1. Choose the right vehicle – You will need to choose a box truck that does not require a CDL license to operate. This will make it easier for you to get started and will allow you to avoid some of the regulatory hurdles associated with operating a commercial vehicle.

2. Get insured – Make sure you are properly insured before starting your business.

This will protect you in case of any accidents or damages that may occur while operating your truck.

3. Get licensed – You will need to obtain the proper licenses and permits before starting your business. This includes obtaining a DOT number and registering your business with the state in which you plan on operating.

4. Create a schedule – Once you have all of the necessary paperwork in order, it’s time to start creating a schedule for your business. Decide how often you want to work and where you want to pick up and drop off your customers’ items.

Non Cdl Car Hauler for Sale

Are you interested in purchasing a non CDL car hauler? If so, there are a few things that you should keep in mind. First and foremost, it is important to remember that these types of haulers are not intended for heavy-duty use.

They are designed for light to moderate hauling jobs, such as transporting cars from one location to another. As such, they may not be suitable for your needs if you require a hauler that can handle more weight or bulkier loads.

When shopping for a non CDL car hauler, it is also important to consider the price.

These types of haulers can range in price from a few hundred dollars to several thousand dollars. It is important to set a budget before beginning your search so that you do not overspend on this purchase. In addition, it is important to compare prices between different sellers before making your final decision.

This will help ensure that you get the best possible deal on your new hauler.

Once you have considered all of these factors, you should be ready to start shopping for your new non CDL car hauler!

Non Cdl Hotshot Startup Cost

Starting a hot shot trucking business can be a great way to earn a good living. But before you get started, it’s important to understand the startup costs involved. Here’s a look at some of the most common expenses:

1. Truck and trailer – The most obvious expense is the truck and trailer you’ll need to haul your loads. If you don’t already have one, expect to spend around $50,000 on a used rig.

2. Insurance – Hot shot trucking is considered high-risk by insurers, so expect to pay higher rates than for other types of trucking businesses.

Expect your insurance to cost around $10,000 per year.

3. Permits and licenses – You’ll need various permits and licenses to operate your hot shot business legally. The cost of these will vary depending on your location and the type of loads you’re hauling but plan on spending several thousand dollars on this upfront.

4.. Maintenance and repairs – Your hot shot rig will require regular maintenance and repairs, so set aside some money each month for this purpose.

Credit: www.upperinc.com

What is the Most You Can Haul Without a Cdl?

If you’re hauling anything more than 26,000 pounds or if you’re towing a vehicle that weighs more than 10,000 pounds, then you need a commercial driver’s license (CDL). However, there are some exceptions. For example, if you’re driving a farm tractor within 150 miles of the farm or if you’re hauling hazardous materials that are properly placarded, then you don’t need a CDL.

Check your state’s requirements for more information.

Can You Make Money Hauling Single Cars?

There are a number of ways that you can make money hauling single cars. One way is to start your own business and advertise your services online or in local publications. You could also work for a company that specializes in car transport and get paid per job.

Finally, you could become an independent contractor and work with multiple companies to haul cars for them. No matter which route you choose, there is potential to make good money hauling single cars.

How to Start Hotshot Trucking Without Cdl?

There are many reasons why someone might want to start hotshot trucking without a CDL. Maybe they don’t have the money for the schooling, or maybe they don’t think they need it because they have experience driving larger vehicles. Whatever the reason, it is possible to get started in hotshot trucking without a CDL.

Here’s how:

1. Look for companies that hire non-CDL drivers. There are some hotshot trucking companies out there that are willing to give new drivers a chance, even if they don’t have their CDL yet.

Do some research and see if you can find one of these companies in your area.

2. Start with a smaller vehicle. If you’re not ready to commit to driving a big rig just yet, that’s okay!

You can start hotshotting with a smaller vehicle like a pickup truck or SUV. Just be sure that whatever vehicle you choose is up for the job – it should be able to tow at least 10,000 pounds.

3. Get your commercial driver’s license (CDL).

Eventually, you’ll need to get your CDL if you want to keep hotshotting long-term. But in the meantime, you can still get started without one by following steps 1 and 2 above.

How to Start-Up a Car Hauling Business?

Assuming you would like a blog post discussing how to start a car hauling business:

If you’re interested in starting your own business, and have a passion for cars, then starting a car hauling business could be the perfect option for you. But where do you start?

What do you need to get started?

Here’s a quick guide on how to start a car hauling business:

1. Decide what services you want to offer.

Do you want to just transport cars, or do you want to provide additional services like cleaning or detailing? Once you know what services you want to offer, research the competition in your area and see what they are offering and at what price points. This will help you determine your pricing structure.

2. Get the necessary insurance coverage for your business. This is important because it will protect your business in case of any accidents or damages that may occur during transport. Make sure to shop around and compare rates from different companies before choosing one.

3. Invest in a good quality trailer. This is important because it will be used to transport the vehicles and needs to be able to withstand the wear and tear of constant use. Look for something that is durable and has features that will make loading and unloading easier such as ramps or lift gates.4 Find some clients!

Is It Profitable to Haul Cars?

Yes, it can be profitable to haul cars. There are a few things to consider when thinking about hauling cars for profit. The first is the cost of fuel.

Fuel prices fluctuate, so you will need to keep an eye on them and plan your routes accordingly. The second is the insurance costs associated with hauling cars. You will need to make sure you have the proper insurance in place before you start hauling cars.

The last thing to consider is the fees associated with using a carhauling service. Some services charge by the mile, while others charge a flat rate. Be sure to compare rates before selecting a service.

How Do I Find My Car Hauling Load?

There are a few things to keep in mind when searching for a car hauling load. First, you’ll need to find a company that is reputable and has experience with car hauling. Next, you’ll want to get quotes from multiple companies so that you can compare prices and services.

Finally, be sure to ask plenty of questions so that you understand the process and what is included in the price.

Local Non CDL Hotshot Car Hauler 2022 (Beginner) How Much I Made in one day – (Updated)

Conclusion

If you’re thinking about starting your own non-CDL car hauling business, there are a few things you need to know. First, you’ll need to find the right vehicle. A used car hauler is a good option, as they’re relatively inexpensive and easy to operate.

Next, you’ll need to obtain the proper insurance coverage for your business. This will protect you in case of an accident or damage to your equipment. Finally, make sure you have a clear understanding of the regulations surrounding non-CDL car haulers.

By following these steps, you can be on your way to starting a successful non-CDL car hauling business.